Filiz Steel, a trusted steel supplier located in Istanbul, Turkey, proudly offers top-notch **Carbon Steel ASTM A105 bars** designed specifically for high-temperature and high-pressure piping systems. These bars are crafted in accordance with the **ASTM A105 specification**, which outlines the standards for **forged carbon steel components** meant for both ambient and high-temperature applications in pressure systems. Renowned for their impressive **mechanical strength, machinability, and weldability**, A105 bars are frequently utilized in the creation of flanges, fittings, valves, and other essential pressure-containing components.

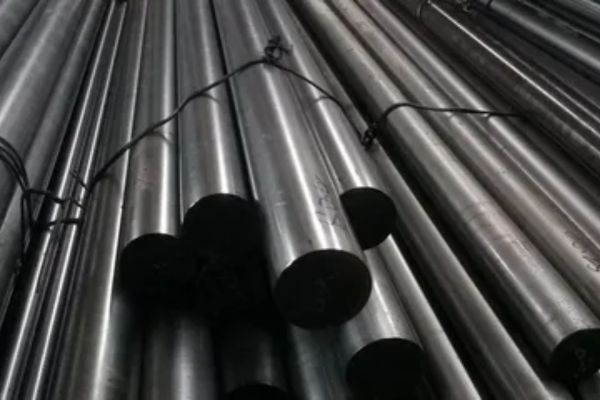

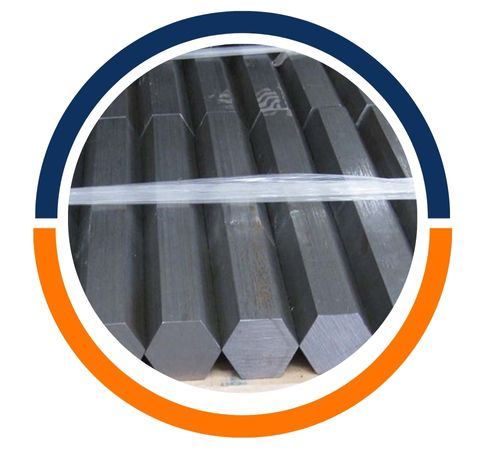

Typically, ASTM A105 carbon steel bars feature **up to 0.35% carbon**, along with carefully controlled amounts of manganese, phosphorus, sulfur, and silicon. This composition results in a **minimum tensile strength of 485 MPa** and a **minimum yield strength of 250 MPa**. These bars exhibit excellent hardness and resistance to deformation under pressure, making them ideal for both forging and machining processes. Filiz Steel provides A105 bars in a variety of shapes, including **round, square, and hexagonal**, and can customize lengths and finishes to meet specific project requirements.

| Standard | ASTM A105, ASME SA105 |

|---|---|

| Dimensions | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Round bar Size | Diameter: 3-~800mm |

| Hex Bar Size | 2-100mm A/F |

| Square Bar Size | 4 to 100mm |

| Angle Bar Size | 3mm*20mm*20mm~12mm*100mm*100mm |

| Rectangular Bars Section | 3.0 to 12.0mm thickness |

| Channel Bar | 80 x 40mm to 150 x 75mm section; 5.0 to 6.0mm thickness |

| Hollow Bar | 32mm OD x 16mm ID to 250mm OD x 200mm ID) |

| Threaded Bar Billet Size | 1/2 to 495mm Diameter |

| Rectangular Size | 33 x 30mm to 295 x 1066mm |

| Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| Surface | Bright, Hot Rolled Pickled, Cold Drawn, Sand Blasting Finished, Polished, Hairline |

| Condition | Hardened & tempered, annealed |

| Technique | Hot Rolled, Cold Drawn, Cold Rolled, Forged Round Bar, Rod |

| Processing | Bar cutting to 650mm |

| Form | Round, Rod, T-Bar, Channel Bar, Precision Ground Bar, Square, Blocks, Round Rod, Rings, Hollow, Triangle, Rectangle, Hex (A/F), Threaded, Half Round Bar, Profiles, Billet, Ingot, I/H Bar, Forging etc. |

| Grade | C | Si | Mn | P | S | Mo | Ni | Cr | Cu | V |

| A105 | 0.35 | 0.10–0.35 | 0.60–1.05 | 0.035 | 0.040 | 0.12 | 0.40 | 0.30 | 0.40 | 0.08 |

| Grade | Yield Strength, Min (MPa ) | Tensile Strength, Min (MPa) | Elongation, min, % |

| A105 | 250 | 485 | 30 |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

A105 bars are widely utilized in **oil and gas refineries**, **chemical processing**, **power generation**, and **petrochemical plants**, playing a crucial role in the production of components that must endure challenging service conditions. Their dependability in high-stress environments, coupled with their cost-effectiveness, makes them a favored material choice across numerous industrial sectors. Filiz Steel guarantees that all A105 bars come with complete certification, including **chemical analysis and mechanical testing**, adhering to international standards such as **ASME, ASTM, and ANSI**.

| ASTM A105 Round Bar Equivalent | ||

|---|---|---|

| STANDARD | UNS | WERKSTOFF NR. |

| ASTM A105 | K03504 | – |

| US Bar | Metric | Japanese | Canadian/ASTM | ||||

| Diameter(Inch) | Carbon Steel A105 Bar Size | Diameter (millimeter) | Carbon Steel A105 Bar Size | Diameter (millimeter) | Carbon Steel A105 Bar Size | Diameter (millimeter2) | Carbon Steel A105 Bar Size |

| 0.250 | #2 | 5 | 5 | 6 | 6 | 100 | 10M |

| 0.375 | #3 | 5.5 | 5.5 | 10 | 10 | 200 | 15M |

| 0.500 | #4 | 6 | 6 | 13 | 13 | 300 | 20M |

| 0.625 | #5 | 7 | 7 | 16 | 16 | 500 | 25M |

| 0.750 | #6 | 8 | 8 | 19 | 19 | 700 | 30M |

| 0.875 | #7 | 9 | 9 | 22 | 22 | 1000 | 35M |

| 1.000 | #8 | 10 | 10 | 25 | 25 | 1500 | 45M |

| 1.125 | #9 | 11 | 11 | 29 | 29 | 2500 | 55M |

| 1.250 | #10 | 12 | 12 | 32 | 32 | ||

| 1.375 | #11 | 14 | 14 | 35 | 35 | ||

| 1.500 | #12 | 16 | 16 | 38 | 38 | ||

| 1.625 | #13 | 18 | 18 | 41 | 41 | ||

| 1.750 | #14 | 20 | 20 | 44 | 44 | ||

| 1.875 | #15 | 22 | 22 | 48 | 48 | ||

| 2.000 | #16 | 25 | 25 | 51 | 51 | ||

| 2.250 | #18 | 28 | 28 | 57 | 57 | ||

| 32 | 32 | ||||||

| 36 | 36 | ||||||

| 40 | 40 | ||||||

| 44 | 44 | ||||||

| 50 | 50 | ||||||

| Diameter in inch | Size in inch/MM | Weight Lbs/ft & Kg/M |

| 1/16 | 0.0625 1.5875 | 0.010 / 0.01488 |

| 1/8 | 0.125 3.175 | 0.042 / 0.062496 |

| 3/32 | 0.0938 2.38252 | 0.0240 / 0.035712 |

| 5/32 | 0.1563 3.97002 | 0.065 / 0.09672 |

| 7/32 | 0.2188 5.55752 | 0.128 / 0.190464 |

| 3/16 | 0.1875 4.7625 | 0.094 / 0.139872 |

| 1/4 | 0.25 6.35 | 0.167 / 0.248496 |

| 5/16 | 0.3125 7.9375 | 0.260 / 0.38688 |

| 9/32 | 0.2813 7.14502 | 0.211 / 0.313968 |

| 3/8 | 0.375 9.525 | 0.376 / 0.559488 |

| 1/2 | 0.5 12.7 | 0.668 / 0.993984 |

| 7/16 | 0.4375 11.1125 | 0.512 / 0.761856 |

| 9/16 | 0.5625 14.2875 | 0.844 / 1.255872 |

| 11/16 | 0.6875 17.4625 | 1.264 / 1.880832 |

| 5/8 | 0.625 15.875 | 1.043 / 1.551984 |

| 3/4 | 0.75 19.05 | 1.502 / 2.234976 |

| 7/8 | 0.875 22.225 | 2.045 / 3.04296 |

| 13/16 | 0.8125 20.6375 | 1.761 / 2.620368 |

| 15/16 | 0.9375 23.8125 | 2.35 / 3.4968 |

| 1 1/16 | 1.0625 26.9875 | 3.012 / 4.481856 |

| 1 | 1 25.4 | 2.671 / 3.974448 |

| 1 1/8 | 1.125 28.575 | 3.38 / 5.02944 |

| 1 1/4 | 1.25 31.75 | 4.173 / 6.209424 |

| 1 3/16 | 1.1875 30.1625 | 3.77 / 5.60976 |

| 1 5/16 | 1.3125 33.3375 | 4.598 / 6.841824 |

Carbon Steel A105 Bars find their extensive applications across different industries on account of its superior strength, durability, and resistance to corrosion. They have major applications in pipelines, pressure vessels, as well as structures in oil & gas, petrochemical, power plant, and ship-building industries. Bars are suitable for flanges, valves, fittings, and parts of machinery in order to sustain high-pressure as well as high-temperature service conditions. Their ease of machinability and weldability make them a favorite for fabrication, construction, and heavy engineering use.

Filiz Steel is a leading manufacturer, supplier and exporter of high-quality Carbon Steel, Alloy Steel, Mild Steel and Galvanized Steel products. Our extensive product range includes Pipes, Tubes, Flanges, Pipe Fittings, Forged Fittings, Sheets and Plates, catering to various industries in Istanbul, Turkey.

Copyright 2025 Filiz Steel. All rights reserved