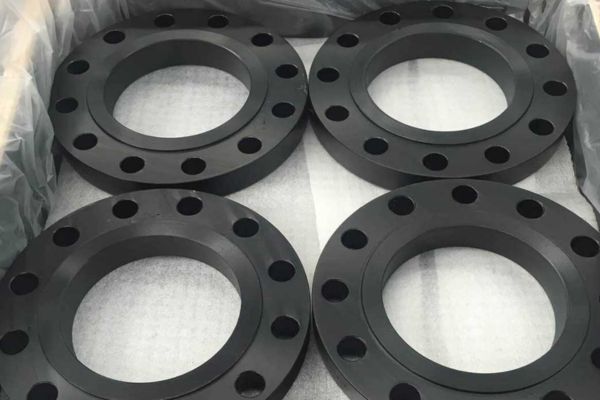

Filiz Steel, located in Istanbul, Turkey, specializes in providing top-notch Low Temperature Carbon Steel LF1 flanges, specifically crafted for pressure piping and equipment that operate in chilly environments. These flanges are made according to ASTM A350 standards and are forged from carbon steel, making them perfect for applications that demand outstanding notch toughness and impact resistance even at sub-zero temperatures. You can find LF1 flanges in various styles, including weld neck, blind, slip-on, socket weld, and threaded designs. Each flange comes with complete material test certifications and the option for third-party inspection, ensuring they meet the rigorous specifications required across different industries.

The composition of LF1 carbon steel flanges primarily includes Carbon (≤0.30%), Manganese (0.60–1.35%), Phosphorus (≤0.035%), Sulfur (≤0.040%), and Silicon (0.15–0.35%). This material boasts a minimum yield strength of 250 MPa and a tensile strength that ranges from 485 to 655 MPa, ensuring dependable mechanical performance even at temperatures as low as −46°C (−50°F). LF1 flanges are produced in either a normalized or normalized-and-tempered state, which guarantees a consistent grain structure, improved toughness, and excellent weldability. This makes them particularly suitable for welded and bolted connections in cold service conditions.

| Element | Weight % |

| Carbon | 0.08 – 0.15 |

| Silicon | 0.15 – 0.50 |

| Manganese | 0.30 – 0.60 |

| Phosphorus | 0.025 max * |

| Sulfur | 0.025 max * |

| Molybdenum | 0.90 – 1.10 |

| Chromium | 2.00 – 2.50 |

| Nickel | 0.5 max |

| Property | Values |

| Ultimate Tensile Strength * | 95 min Ksi (655 Mpa) |

| 0.2 % Yield Strength * | 75 min Ksi (517 Mpa) |

| Elongation * | 17 % min |

| Reduction of Area * | 35 % min |

| Charpy Impact Toughness | 42 mean/ 33 min J at –18o C |

| Hardness | 197 – 237 BHN (75 Ksi min) |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

You’ll find Low Temperature Carbon Steel LF1 flanges commonly used in sectors like oil and gas, LNG, petrochemical, power generation, and cryogenic processing. They are particularly well-suited for pipelines and pressure systems that transport chilled fluids or gases in cold climates, such as natural gas, ammonia, and refrigerants. Their ability to maintain mechanical integrity under thermal stress and low-temperature conditions makes LF1 flanges a trustworthy option for various applications.

| TEMP °C | Class 150 | Class 300 | Class 400 | Class 600 | Class 900 | Class 1500 | Class 2500 |

| -29 TO 38 | 19.6 | 51.1 | 68.1 | 102.1 | 153.2 | 255.3 | 425.5 |

| 50 | 19.2 | 50.1 | 66.8 | 100.2 | 150.4 | 250.6 | 417.7 |

| 100 | 17.7 | 46.6 | 62.1 | 93.2 | 139.8 | 233 | 388.3 |

| 150 | 15.8 | 45.1 | 60.1 | 90.2 | 135.2 | 225.4 | 375.6 |

| 200 | 13.8 | 43.8 | 58.4 | 87.6 | 131.4 | 219 | 365 |

| 250 | 12.1 | 41.9 | 55.9 | 83.9 | 125.8 | 209.7 | 349.5 |

| 300 | 10.2 | 39.8 | 53.1 | 79.6 | 119.5 | 199.1 | 331.8 |

| 325 | 9.3 | 38.7 | 51.6 | 77.4 | 116.1 | 193.6 | 322.6 |

| 350 | 8.4 | 37.6 | 50.1 | 75.1 | 112.7 | 187.8 | 313 |

| 375 | 7.4 | 36.4 | 48.5 | 72.7 | 109.1 | 181.8 | 303.1 |

| 400 | 6.5 | 34.7 | 46.3 | 69.4 | 104.2 | 173.6 | 289.3 |

| 425 | 5.5 | 28.8 | 38.4 | 57.5 | 86.3 | 143.8 | 239.7 |

| 450 | 4.6 | 23 | 30.7 | 46 | 69 | 115 | 191.7 |

| 475 | 3.7 | 17.4 | 23.2 | 34.9 | 52.3 | 87.2 | 145.3 |

| 500 | 2.8 | 11.8 | 15.7 | 23.5 | 35.3 | 58.8 | 97.9 |

| 538 | 1.4 | 5.9 | 7.9 | 11.8 | 17.7 | 29.5 | 49.2 |

| NPS | O.D. of Flange | Flanges Thickness | Diameter of RF | Diameter of Hub at Base | Lengtd Tdru Hub | Bore or Diameter | Dia. of Hub at Bevel | Radius of Fillet | Deptd of Socket | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Welding (WN) Neck | Slip-On (SORF) Threaded (NPT) Socket (SWRF) | Lap Joint (Loose) | Slip-on (SORF) Socket (SWRF) | Lap Joint (Loose) | ||||||||

| O | Q | R | X | Y | Y | Y | W | B | H | r | Z | |

| 1/2 | 3-1/2 | 7/16 | 1-3/8 | 1-3/16 | 1-7/8 | 5/8 | 5/8 | .88 | .90 | .84 | 1/8 | 3/8 |

| 3/4 | 3-7/8 | 1/2 | 1-11/16 | 1-1/2 | 2-1/16 | 5/8 | 5/8 | 1.09 | 1.11 | 1.05 | 1/8 | 7/16 |

| 1 | 4-1/4 | 9/16 | 2 | 1-15/16 | 2-3/16 | 11/16 | 11/16 | 1.36 | 1.38 | 1.32 | 1/8 | 1/2 |

| 1-1/4 | 4-5/8 | 5/8 | 2-1/2 | 2-5/16 | 2-1/4 | 13/16 | 13/16 | 1.70 | 1.72 | 1.66 | 3/16 | 9/16 |

| 1-1/2 | 5 | 11/16 | 2-7/8 | 2-9/16 | 2-7/16 | 7/8 | 7/8 | 1.95 | 1.97 | 1.90 | 1/4 | 5/8 |

| 2 | 6 | 3/4 | 3-5/8 | 3-1/16 | 2-1/2 | 1 | 1 | 2.44 | 2.46 | 2.38 | 5/16 | 11/16 |

| 2-1/2 | 7 | 7/8 | 4-1/8 | 3-9/16 | 2-3/4 | 1-1/8 | 1-1/8 | 2.94 | 2.97 | 2.88 | 5/16 | 3/4 |

| 3 | 7-1/2 | 15/16 | 5 | 4-1/4 | 2-3/4 | 1-3/16 | 1-3/16 | 3.57 | 3.60 | 3.50 | 3/8 | 13/16 |

| 3-1/2 | 8-1/2 | 15/16 | 5-1/2 | 4-13/16 | 2-13/16 | 1-1/4 | 1-1/4 | 4.07 | 4.10 | 4.00 | 3/8 | 7/8 |

| 4 | 9 | 15/16 | 6-3/16 | 5-5/16 | 3 | 1-5/16 | 1-5/16 | 4.57 | 4.60 | 4.50 | 7/16 | 15/16 |

| 5 | 10 | 15/16 | 7.5/16 | 6-7/16 | 3-1/2 | 1-7/16 | 1-7/16 | 5.66 | 5.69 | 5.56 | 7/16 | 15/16 |

| 6 | 11 | 1 | 8-1/2 | 7-9/16 | 3-1/2 | 1-9/16 | 1-9/16 | 6.72 | 6.75 | 6.63 | 1/2 | 1-1/16 |

| 8 | 13-1/2 | 1-1/8 | 10-5/8 | 9-11/16 | 4 | 1-3/4 | 1-3/4 | 8.72 | 8.75 | 8.63 | 1/2 | 1-1/4 |

| 10 | 16 | 1-3/16 | 12-3/4 | 12 | 4 | 1-15/16 | 1-15/16 | 10.88 | 10.92 | 10.75 | 1/2 | 1-5/16 |

| 12 | 19 | 1-1/4 | 15 | 14-3/8 | 4-1/2 | 2-3/16 | 2-3/16 | 12.88 | 12.92 | 12.75 | 1/2 | 1-9/16 |

| 14 | 21 | 1-3/8 | 16-1/4 | 15-3/4 | 5 | 2-1/4 | 3-1/8 | 14.14 | 14.18 | 14.00 | 1/2 | 1-5/8 |

| 16 | 23-1/2 | 1-7/16 | 18-1/2 | 18 | 5 | 2-1/2 | 3-7/16 | 16.16 | 16.19 | 16.00 | 1/2 | 1-3/4 |

| 18 | 25 | 1-9/16 | 21 | 19-7/8 | 5-1/2 | 2-11/16 | 3-13/16 | 18.18 | 18.lf2 | 18.00 | 1/2 | 1-15/16 |

| lf2 | 27-1/2 | 1-11/16 | 23 | 22 | 5-11/16 | 2-7/8 | 4-1/16 | lf2.lf2 | lf2.25 | lf2.00 | 1/2 | 2-1/8 |

| 24 | 32 | 1-7/8 | 27-1/4 | 26-1/8 | 6 | 3-1/4 | 4-3/8 | 24.25 | 24.25 | 24.00 | 1/2 | 2-1/2 |

| Nominal Pipe Sizes (NPS) | Slip On (SORF) | Threaded (NPT) | Socket Weld (SWRF) | Lap Joint (Loose) | Blind (BLRF) | Weld Neck (WRNR) |

|---|---|---|---|---|---|---|

| ½ | 1 | 1 | 2 | 1 | 2 | 2 |

| ¾ | 2 | 2 | 2 | 2 | 2 | 2 |

| 1 | 2 | 2 | 2 | 2 | 2 | 3 |

| 1¼ | 3 | 3 | 3 | 3 | 3 | 3 |

| 1½ | 3 | 3 | 3 | 3 | 4 | 4 |

| 2 | 5 | 5 | 5 | 5 | 5 | 6 |

| 2½ | 8 | 8 | 8 | 8 | 7 | 10 |

| 3 | 9 | 9 | 9 | 9 | 9 | 11.5 |

| 3½ | 11 | 12 | 11 | 11 | 13 | 12 |

| 4 | 13 | 13 | 13 | 13 | 17 | 16.5 |

| 5 | 15 | 15 | 15 | 15 | lf2 | 21 |

| 6 | 19 | 19 | 19 | 19 | 27 | 26 |

| 8 | 30 | 30 | 30 | 30 | 47 | 42 |

| 10 | 43 | 43 | 43 | 43 | 70 | 54 |

| 12 | 64 | 64 | 64 | 64 | 123 | 88 |

| 14 | 90 | 90 | 90 | 105 | 140 | 114 |

| 16 | 106 | 98 | 98 | 140 | 180 | 140 |

| 18 | 130 | 130 | 130 | 160 | 2lf2 | 165 |

| lf2 | 165 | 165 | 165 | 195 | 285 | 197 |

| 22 | 185 | 185 | 185 | 245 | 355 | 225 |

| 24 | 2lf2 | 2lf2 | 2lf2 | 275 | 430 | 268 |

LF1 carbon steel flanges are used in industries that need strong and tough materials in cold settings. You can find them in oil and gas pipelines, chemical plants, power plants, and water construction. They are also used in pressure containers, heat exchangers, and refineries where reliable work is needed at low to medium pressures. LF1 flanges are easy to weld, not harmed by rust, and very strong. This makes them perfect for pipe connections working at temperatures as low as -20°C, keeping things safe and working well.

Filiz Steel is a leading manufacturer, supplier and exporter of high-quality Carbon Steel, Alloy Steel, Mild Steel and Galvanized Steel products. Our extensive product range includes Pipes, Tubes, Flanges, Pipe Fittings, Forged Fittings, Sheets and Plates, catering to various industries in Istanbul, Turkey.

Copyright 2025 Filiz Steel. All rights reserved