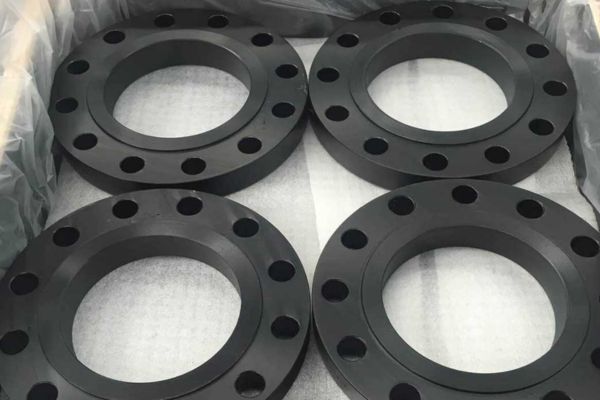

Filiz Steel, based in Istanbul, Turkey, is a reliable manufacturer and supplier of Low Temperature Carbon Steel LF3 Flanges. These flanges are crafted to meet the demands of cryogenic and sub-zero temperature applications, ensuring high-quality piping components. They boast exceptional toughness, durability, and resistance to brittle fracture, making them ideal for industries like oil and gas, petrochemical, LNG, and refrigeration. Filiz Steel guarantees that its LF3 flanges adhere to ASTM A350 and ASME standards, providing precise dimensional accuracy, consistent mechanical properties, and excellent weldability. With state-of-the-art production facilities and rigorous quality control, the company delivers LF3 flanges for critical low-temperature piping systems around the globe.

Manufactured from carbon-manganese steel, Low Temperature Carbon Steel LF3 Flanges are designed with carefully controlled carbon and alloying elements to boost strength and toughness in low temperatures. They demonstrate impressive tensile and yield strength, along with outstanding impact resistance even at temperatures as low as -46°C (-50°F). Their fine-grain microstructure helps prevent brittle fracture under pressure, while also ensuring good weldability and machinability for easy integration into piping systems. LF3 flanges are built to perform reliably in challenging low-temperature and high-pressure environments.

| Material Specification Of : | ASTM A350 LF3 Flanges |

|---|---|

| Pressure Rating | Class 150 To Class 2500 |

| High Temperature | Above 200°C (400°F) For Class 150 Or Above 400°C (750°F) |

| Low Temperature | Above -29 Degree C (−20°F) |

| Russian-Standard Flanges | GOST 12820 / 12821-80, DIN, UNI, EN 1092-1 |

| South African Standard Flanges | SANSflanges And SABS flanges |

| Surface Finish | smooth, concentric serrated, stock |

| Gaskets Types | Full Face Gasket Flat Ring Gasket Metallic Ring Gakset |

| Advantages Of Pipe Flange | Used to Connect Pipe System Easy Repair Pipe System Assembled Without Welding |

| Common Types Of Flanges: | Slip On (SORF), Weld Neck (WNRF), Blind (BLRF), Lap Joint (Loose), Threaded (NPT), Socket-Weld (SWRF) |

| Special Types Of Flanges : | Nipoflange, Elboflange, Latroflange, Swivel Flange, Expanding Flange, Reducing Flange, Weldoflange |

| Marking Standard | Name of Manufacturer Schedule Type of Flange Facing Nominal Pipe Size Pressure Class ASME B16 Designation |

| Standard Cover : | pressure ratings & temperature ratings, materials, marking, dimensions, weight, tolerances, testing |

| Contact Faces | RTJ (Ring Type Joint), FF (Flat Face), RF (Raised Face), T/G (Tongue And Groove ), M/F (Male And Female) |

| Size Chart | Normal Pipe Size 1/2 to NPS 24″ |

| Thickness | Normal Pipe Size ≤ 18 |

| Bore Diameter | Normal Pipe ≤ 10 |

| Flanges Standards | EN 1092-1, JIS, ASME B16.5, ASME B16.47 type A, UNI, DIN |

| Bolt Type | high strength bolts medium strength bolts low strength bolts |

| European Standard Flanges | JIS B2220 Flanges (5k to 30k) and KS1503 flanges |

| Element | Composition |

|---|---|

| Carbon, maximum | 0.20 maximum |

| Manganese | 0.90 maximum |

| Phosphorus, maximum | 0.035 maximum |

| Sulfur, maximum | 0.040 maximum |

| Silicon [Note A] | 0.20–0.35 |

| Nickel | 3.3–3.7 |

| Chromium | 0.30 maximum [Note C] |

| Molybdenum | 0.12 maximum [Note C] |

| Copper | 0.40 maximum |

| Columbium | 0.02 maximum |

| Vanadium | 0.03 maximum |

Tensile Strength, minimum: | 70,000 psi (485 MPa] |

Minimum. Yield Point: | 36,000 psi [250 MPa] |

Reduction of area, minimum: | 30% minimum |

Hardness, HB, maximum | 187 |

We provide products that come with both mill test certificates and third-party test certificates, ensuring the highest standards of quality and compliance.

Filiz Steel is one of the most prominent manufacturers and suppliers of superior quality Low Temperature Carbon Steel LF3 Flanges in Istanbul, Turkey. As experts in steel solutions, we supply a complete spectrum of products like Carbon Steel, Alloy Steel, Mild Steel, and Galvanized Steel. Our product range comprises Pipes, Tubes, Flanges, Pipe Fittings, Forged Fittings, Sheets, and Plates. Known for our reliable delivery and first-rate customer service, we are committed to supplying high-quality steel materials that guarantee durability and excellent performance in numerous industrial applications.

| TEMP °C | Class 150 | Class 300 | Class 400 | Class 600 | Class 900 | Class 1500 | Class 2500 |

| -29 TO 38 | 19.6 | 51.1 | 68.1 | 102.1 | 153.2 | 255.3 | 425.5 |

| 50 | 19.2 | 50.1 | 66.8 | 100.2 | 150.4 | 250.6 | 417.7 |

| 100 | 17.7 | 46.6 | 62.1 | 93.2 | 139.8 | 233 | 388.3 |

| 150 | 15.8 | 45.1 | 60.1 | 90.2 | 135.2 | 225.4 | 375.6 |

| 200 | 13.8 | 43.8 | 58.4 | 87.6 | 131.4 | 219 | 365 |

| 250 | 12.1 | 41.9 | 55.9 | 83.9 | 125.8 | 209.7 | 349.5 |

| 300 | 10.2 | 39.8 | 53.1 | 79.6 | 119.5 | 199.1 | 331.8 |

| 325 | 9.3 | 38.7 | 51.6 | 77.4 | 116.1 | 193.6 | 322.6 |

| 350 | 8.4 | 37.6 | 50.1 | 75.1 | 112.7 | 187.8 | 313 |

| 375 | 7.4 | 36.4 | 48.5 | 72.7 | 109.1 | 181.8 | 303.1 |

| 400 | 6.5 | 34.7 | 46.3 | 69.4 | 104.2 | 173.6 | 289.3 |

| 425 | 5.5 | 28.8 | 38.4 | 57.5 | 86.3 | 143.8 | 239.7 |

| 450 | 4.6 | 23 | 30.7 | 46 | 69 | 115 | 191.7 |

| 475 | 3.7 | 17.4 | 23.2 | 34.9 | 52.3 | 87.2 | 145.3 |

| 500 | 2.8 | 11.8 | 15.7 | 23.5 | 35.3 | 58.8 | 97.9 |

| 538 | 1.4 | 5.9 | 7.9 | 11.8 | 17.7 | 29.5 | 49.2 |

| TEMP °C | 150 | 300 | 400 | 600 | 900 | 1500 | 2500 |

| NPS | O.D. of Flange | Flanges Thickness | Diameter of RF | Diameter of Hub at Base | Lengtd Tdru Hub | Bore or Diameter | Dia. of Hub at Bevel | Radius of Fillet | Deptd of Socket | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Welding (WN) Neck | Slip-On (SORF) Threaded (NPT) Socket (SWRF) | Lap Joint (Loose) | Slip-on (SORF) Socket (SWRF) | Lap Joint (Loose) | ||||||||

| O | Q | R | X | Y | Y | Y | W | B | H | r | Z | |

| 1/2 | 3-1/2 | 7/16 | 1-3/8 | 1-3/16 | 1-7/8 | 5/8 | 5/8 | .88 | .90 | .84 | 1/8 | 3/8 |

| 3/4 | 3-7/8 | 1/2 | 1-11/16 | 1-1/2 | 2-1/16 | 5/8 | 5/8 | 1.09 | 1.11 | 1.05 | 1/8 | 7/16 |

| 1 | 4-1/4 | 9/16 | 2 | 1-15/16 | 2-3/16 | 11/16 | 11/16 | 1.36 | 1.38 | 1.32 | 1/8 | 1/2 |

| 1-1/4 | 4-5/8 | 5/8 | 2-1/2 | 2-5/16 | 2-1/4 | 13/16 | 13/16 | 1.70 | 1.72 | 1.66 | 3/16 | 9/16 |

| 1-1/2 | 5 | 11/16 | 2-7/8 | 2-9/16 | 2-7/16 | 7/8 | 7/8 | 1.95 | 1.97 | 1.90 | 1/4 | 5/8 |

| 2 | 6 | 3/4 | 3-5/8 | 3-1/16 | 2-1/2 | 1 | 1 | 2.44 | 2.46 | 2.38 | 5/16 | 11/16 |

| 2-1/2 | 7 | 7/8 | 4-1/8 | 3-9/16 | 2-3/4 | 1-1/8 | 1-1/8 | 2.94 | 2.97 | 2.88 | 5/16 | 3/4 |

| 3 | 7-1/2 | 15/16 | 5 | 4-1/4 | 2-3/4 | 1-3/16 | 1-3/16 | 3.57 | 3.60 | 3.50 | 3/8 | 13/16 |

| 3-1/2 | 8-1/2 | 15/16 | 5-1/2 | 4-13/16 | 2-13/16 | 1-1/4 | 1-1/4 | 4.07 | 4.10 | 4.00 | 3/8 | 7/8 |

| 4 | 9 | 15/16 | 6-3/16 | 5-5/16 | 3 | 1-5/16 | 1-5/16 | 4.57 | 4.60 | 4.50 | 7/16 | 15/16 |

| 5 | 10 | 15/16 | 7.5/16 | 6-7/16 | 3-1/2 | 1-7/16 | 1-7/16 | 5.66 | 5.69 | 5.56 | 7/16 | 15/16 |

| 6 | 11 | 1 | 8-1/2 | 7-9/16 | 3-1/2 | 1-9/16 | 1-9/16 | 6.72 | 6.75 | 6.63 | 1/2 | 1-1/16 |

| 8 | 13-1/2 | 1-1/8 | 10-5/8 | 9-11/16 | 4 | 1-3/4 | 1-3/4 | 8.72 | 8.75 | 8.63 | 1/2 | 1-1/4 |

| 10 | 16 | 1-3/16 | 12-3/4 | 12 | 4 | 1-15/16 | 1-15/16 | 10.88 | 10.92 | 10.75 | 1/2 | 1-5/16 |

| 12 | 19 | 1-1/4 | 15 | 14-3/8 | 4-1/2 | 2-3/16 | 2-3/16 | 12.88 | 12.92 | 12.75 | 1/2 | 1-9/16 |

| 14 | 21 | 1-3/8 | 16-1/4 | 15-3/4 | 5 | 2-1/4 | 3-1/8 | 14.14 | 14.18 | 14.00 | 1/2 | 1-5/8 |

| 16 | 23-1/2 | 1-7/16 | 18-1/2 | 18 | 5 | 2-1/2 | 3-7/16 | 16.16 | 16.19 | 16.00 | 1/2 | 1-3/4 |

| 18 | 25 | 1-9/16 | 21 | 19-7/8 | 5-1/2 | 2-11/16 | 3-13/16 | 18.18 | 18.lf2 | 18.00 | 1/2 | 1-15/16 |

| lf2 | 27-1/2 | 1-11/16 | 23 | 22 | 5-11/16 | 2-7/8 | 4-1/16 | lf2.lf2 | lf2.25 | lf2.00 | 1/2 | 2-1/8 |

| 24 | 32 | 1-7/8 | 27-1/4 | 26-1/8 | 6 | 3-1/4 | 4-3/8 | 24.25 | 24.25 | 24.00 | 1/2 | 2-1/2 |

| Nominal Pipe Sizes (NPS) | Slip On (SORF) | Threaded (NPT) | Socket Weld (SWRF) | Lap Joint (Loose) | Blind (BLRF) | Weld Neck (WRNR) |

|---|---|---|---|---|---|---|

| ½ | 1 | 1 | 2 | 1 | 2 | 2 |

| ¾ | 2 | 2 | 2 | 2 | 2 | 2 |

| 1 | 2 | 2 | 2 | 2 | 2 | 3 |

| 1¼ | 3 | 3 | 3 | 3 | 3 | 3 |

| 1½ | 3 | 3 | 3 | 3 | 4 | 4 |

| 2 | 5 | 5 | 5 | 5 | 5 | 6 |

| 2½ | 8 | 8 | 8 | 8 | 7 | 10 |

| 3 | 9 | 9 | 9 | 9 | 9 | 11.5 |

| 3½ | 11 | 12 | 11 | 11 | 13 | 12 |

| 4 | 13 | 13 | 13 | 13 | 17 | 16.5 |

| 5 | 15 | 15 | 15 | 15 | lf2 | 21 |

| 6 | 19 | 19 | 19 | 19 | 27 | 26 |

| 8 | 30 | 30 | 30 | 30 | 47 | 42 |

| 10 | 43 | 43 | 43 | 43 | 70 | 54 |

| 12 | 64 | 64 | 64 | 64 | 123 | 88 |

| 14 | 90 | 90 | 90 | 105 | 140 | 114 |

| 16 | 106 | 98 | 98 | 140 | 180 | 140 |

| 18 | 130 | 130 | 130 | 160 | 2lf2 | 165 |

| lf2 | 165 | 165 | 165 | 195 | 285 | 197 |

| 22 | 185 | 185 | 185 | 245 | 355 | 225 |

| 24 | 2lf2 | 2lf2 | 2lf2 | 275 | 430 | 268 |

These flanges are widely utilized in industries that demand dependable performance in extreme cold. You’ll find them in oil and gas pipelines, LNG storage and processing facilities, chemical and petrochemical plants, and cryogenic refrigeration systems. Additionally, LF3 flanges are essential in offshore platforms, refineries, and power plants where low-temperature toughness and longevity are crucial. By combining strength, impact resistance, and cost-effectiveness, LF3 flanges offer safe and durable solutions for sub-zero and cryogenic service applications.

Filiz Steel is a leading manufacturer, supplier and exporter of high-quality Carbon Steel, Alloy Steel, Mild Steel and Galvanized Steel products. Our extensive product range includes Pipes, Tubes, Flanges, Pipe Fittings, Forged Fittings, Sheets and Plates, catering to various industries in Istanbul, Turkey.

Copyright 2025 Filiz Steel. All rights reserved